- home

-

Products

- Products

- Metrici Custom Applications

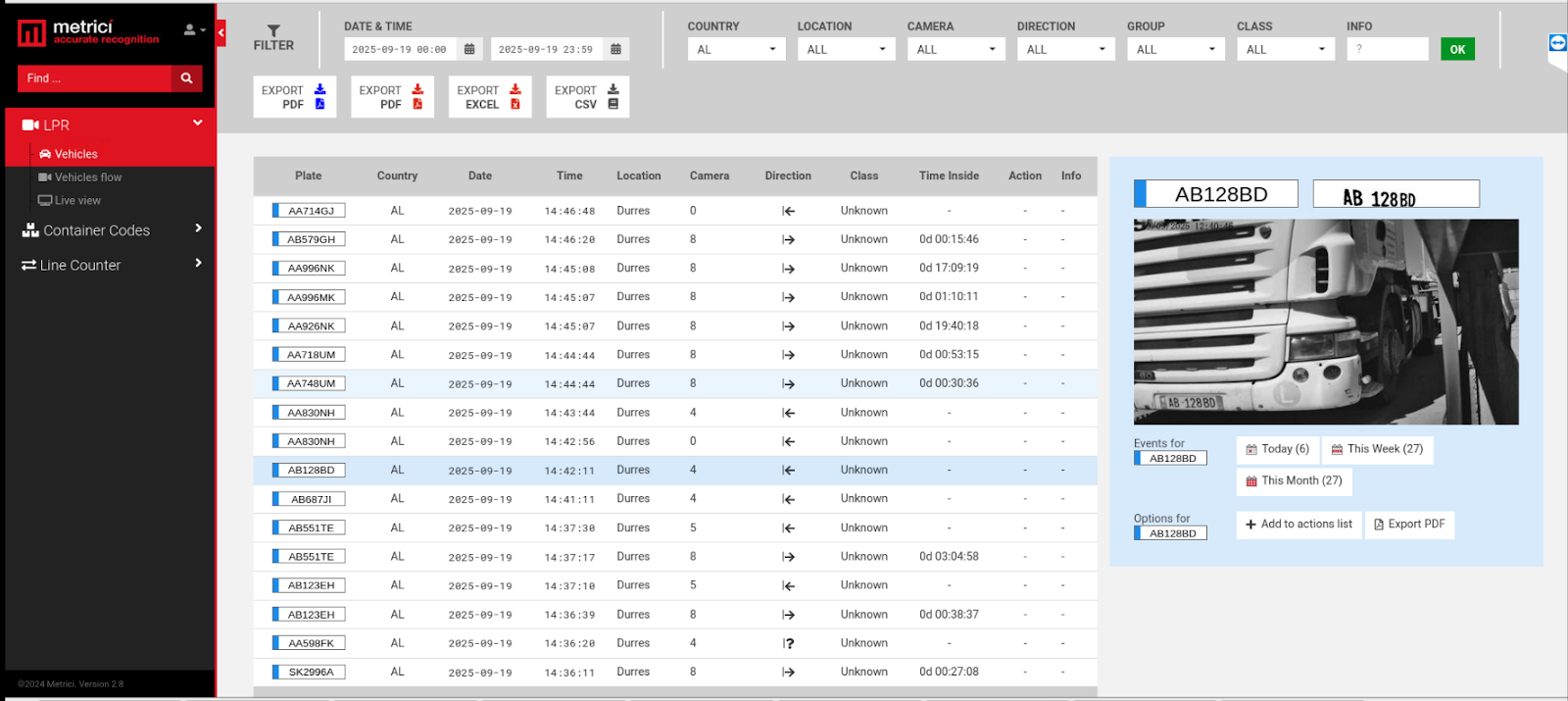

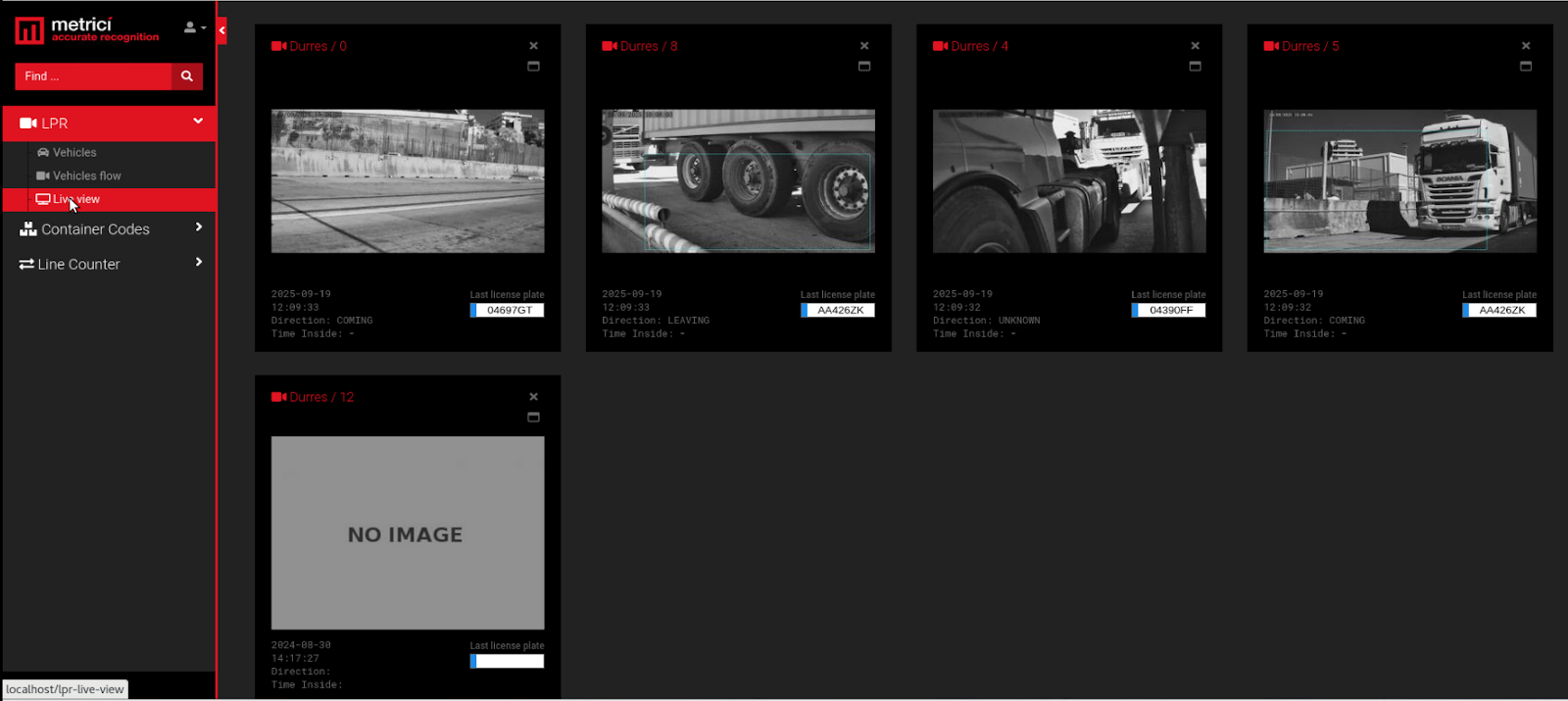

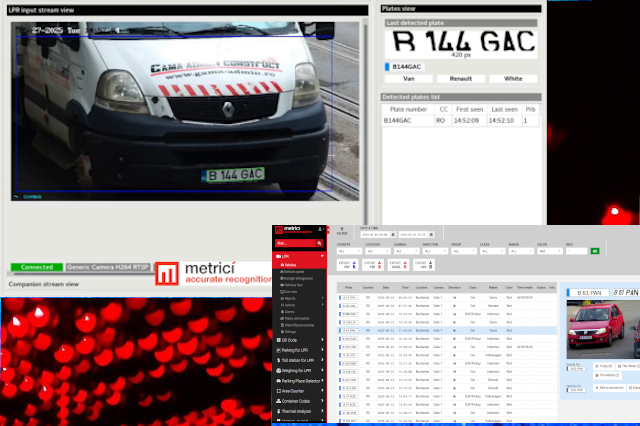

- Metrici LPR

- Metrici LPR Parking Module

- Metrici LPR Toll Station Module

- Metrici LPR Weighing Module

- Metrici PPD

- Metrici Area Counter

- Metrici Line Counter

- Metrici QR Code Reader

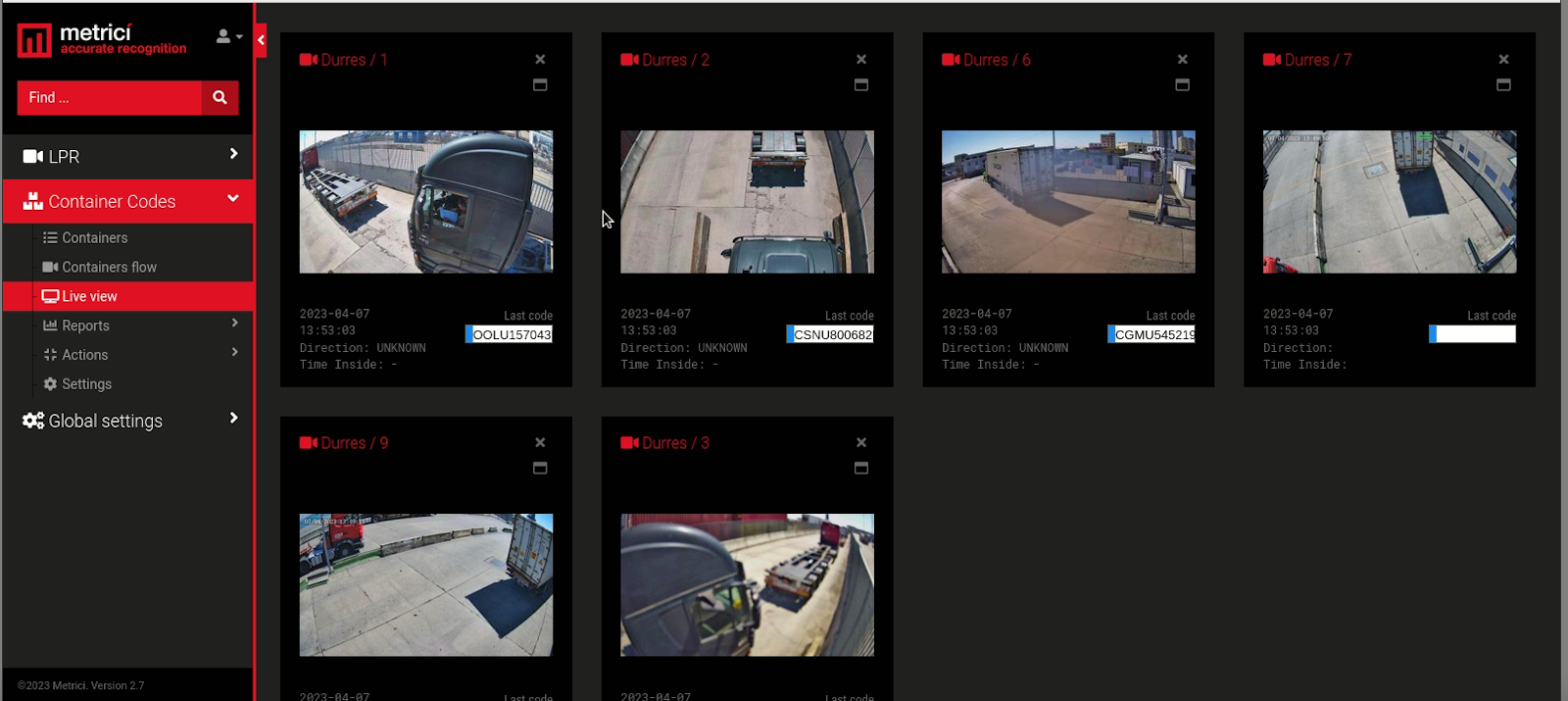

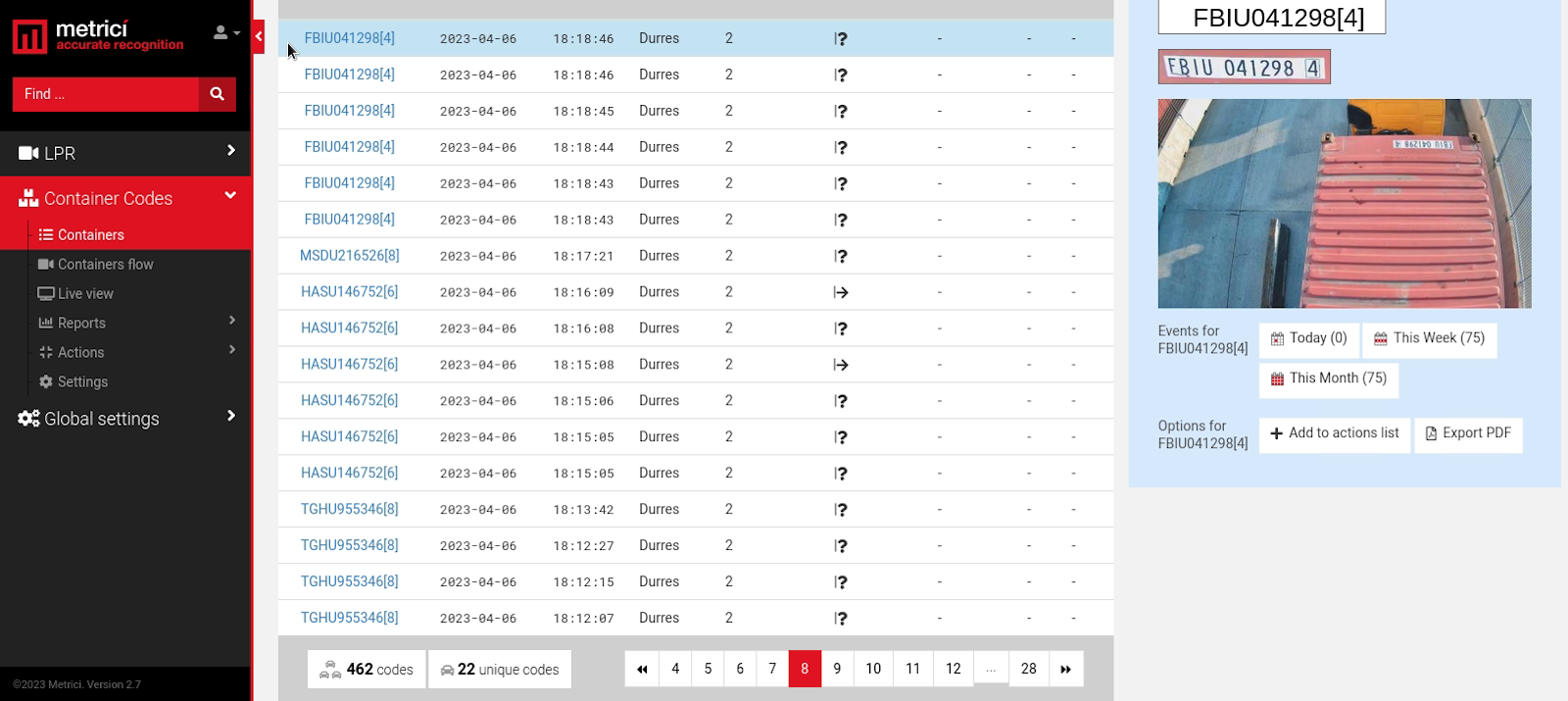

- Metrici Container Code Recognition

- Metrici Thermal Analyzer

- Metrici Car Kit

- Metrici Server Systems

- Metrici Observer Radar

- Metrici LED Display

- Metrici MultiController

- Metrici LAN Controller

- case studies

- Applications

- Resources

- news

- videos

- Contact

Case study: Albania

Durres port, surveilled by Metrici CCR, LPR, PPD and Line Counter

Mission

Port of Durres is the main port of Albania and the only one which is handling containers. Initially this port started with containers about 15 years ago and could only handle 500-800 TEU per year, and since then, containers started to take over the general cargo. At this point, this port is handling around 100.000 TEU per year. Approx 603,000t of cargo and 770,800 passengers are handled annually.

Durres port is the main gateway of Albania and serves 79% of Albanian imports and 88% of exports, where more than 85% of the seaborne cargoes go through this port.

Solution

Since this port is very new in containers handling operations, and the container traffic forecast is optimistic, there are a number of issues that were considered when Metrici was approached to monitor traffic inside the premises.

Our partners from Albascan called Metrici to find together a solution for improving workflow and security.Port of Durres represents the main interface of the Albanian intermodal trade and serves as the gateway of Albania. Being just 40 km from the capital, Durres port has a very strategic position regarding the integrated European transport corridors, making cargoes and passengers move easily to the center of European continent.

As the the traffic grew and will continue, so the port handlers needed to adapt and expand. Metrici was called in for its AI projects. Several Metrici solutions are used on the access routes and terminals in the Durres port.

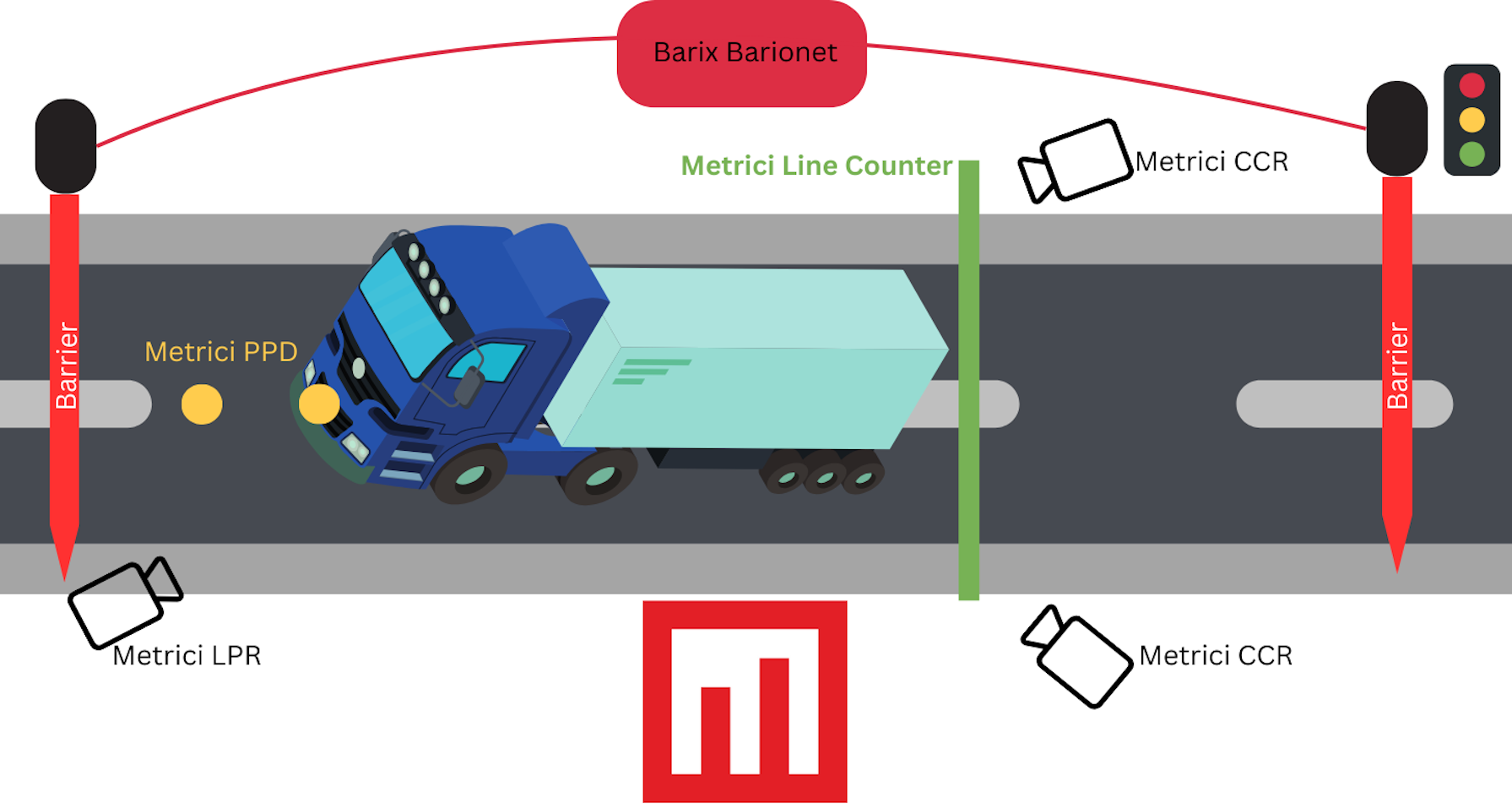

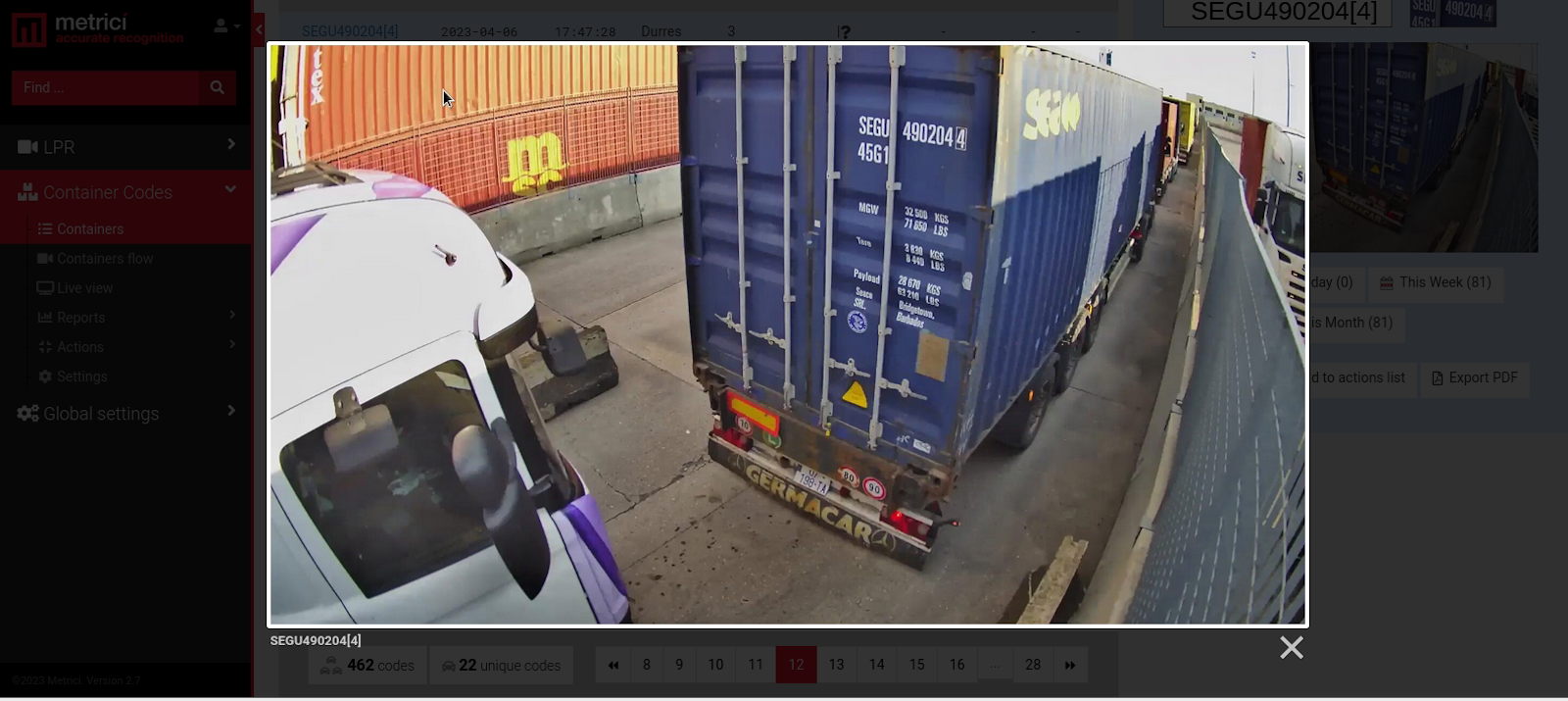

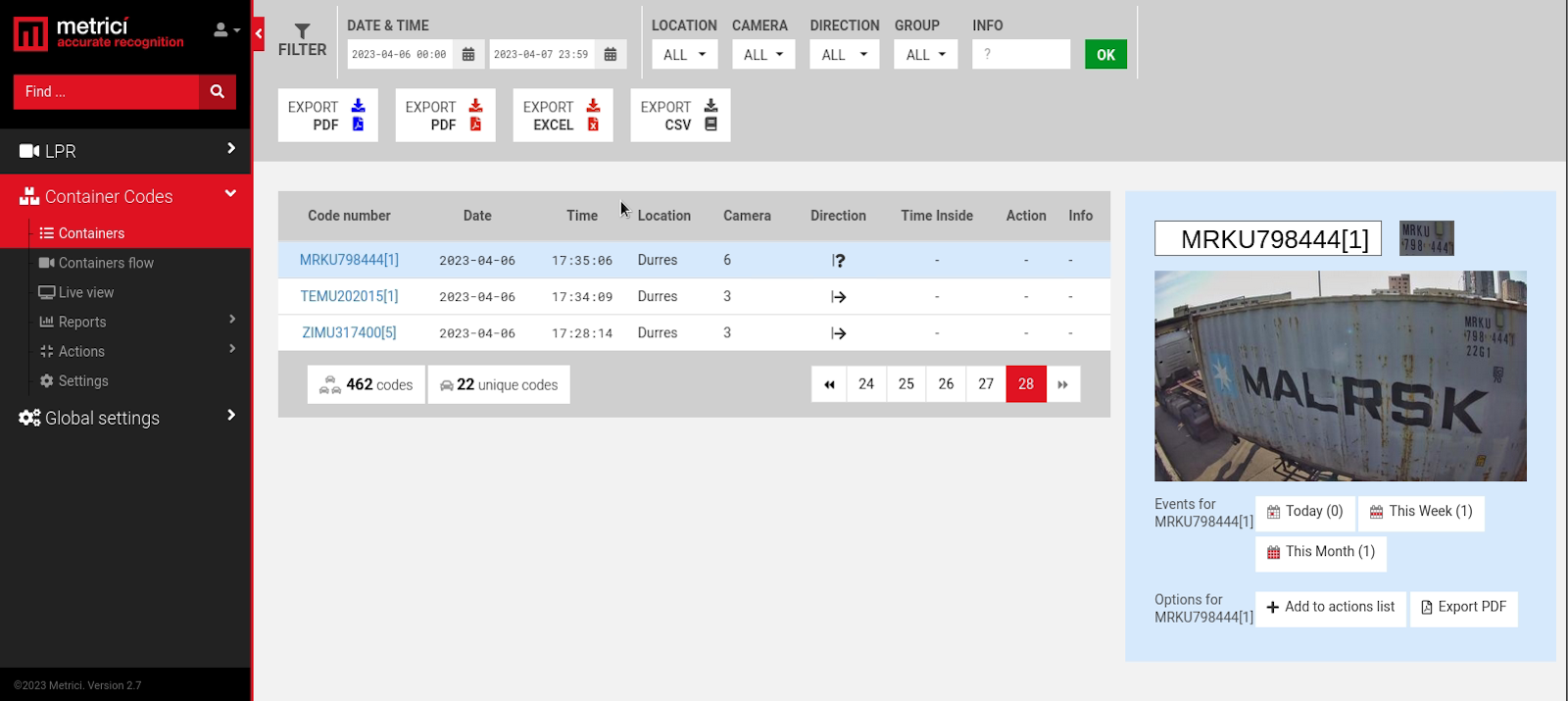

A number of Metrici detection engines are working together, where some are freeflow, some are triggered by others. License Plate Recognition, Container Code Recognition, Line Counter and Parking Place Detector detection engines are used to record activity and read both container codes as well as license plates and establish a god management and security.

How the system works

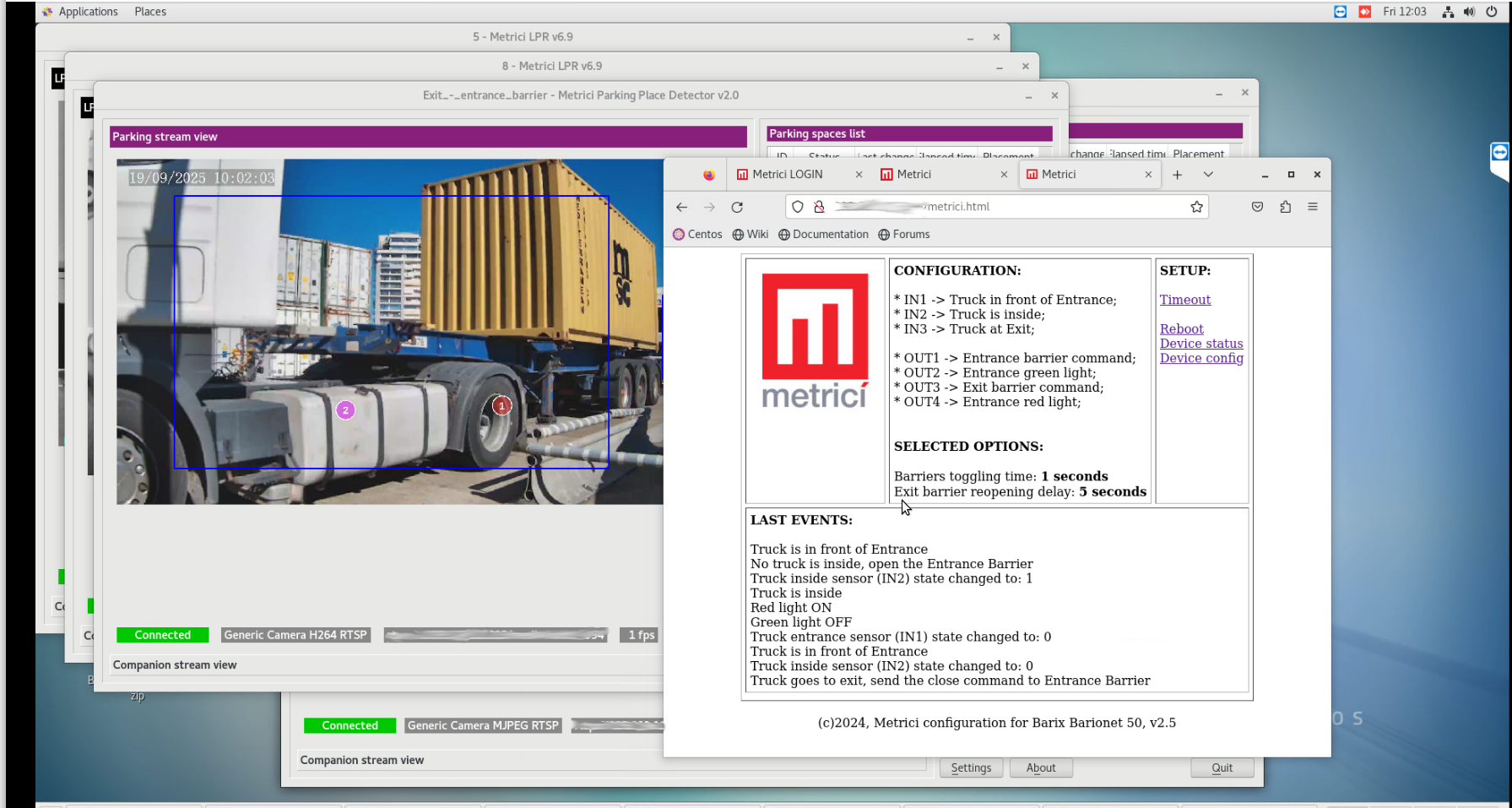

For the beginning, a total number of 14 detection engines are used: 5 Metrici LPR engines, 6 Metrici CCR engines, 1 Metrici Line Counter, 2 Metrici Parking Place Detector.

On the access road in the port, a Metrici Line Counter Engine triggers the beginning of the detections. As the engine is activated, it triggers all events including CCR reading with a search interval of around 30 seconds, as the truck move at rondom speeds and you never know when and where a code will be visible- on the sides or on top of the container, so more CCR engines search for a code in the frames. As soon as the code is seen it is recorded. As the truck moves when certain PPD engines are triggered, a LPR reading is done as Metrici knows that the truck reached the desired position. Also, a traffic light is switched to red light. The license plate is associated in database with the container code read before. As the PPD engines are still "busy" Metrici knows to not open the barrier for another truck. As the places are free, the next truck in line can enter, and the first barrier is lifted. The detections and readings, along the photos from the time of detection (plate number and container's code) are saved together in database and also sent to third party management system. The data also include timestamp, direction, camera and other metadata. All around the port, asa well as at entries and exit some other Metrici LPRand Metrici CCR engines are placed for the administrators to know exactly where each truck is and where it was.

Truck Access Flow with Metrici EnginesProcess Overview Step by Step

The truck access process in the port is managed through a sequence of Metrici engines that coordinate Container Code Recognition, license plate reading, and traffic control. The system ensures accurate identification. Step-by-Step FlowA Metrici Line Counter Engine detects the presence of a truck on the access road.

This detection triggers the start of the recognition process.

Once activated, the CCR engine begins scanning for container codes.

The search interval is approximately 30 seconds, accounting for variable truck speeds and unpredictable code placement that can be read (sides or top of the container).

Multiple CCR engines may operate simultaneously to increase detection accuracy.

As the truck moves forward, PPD engines confirm when it reaches the designated position.

At this point, an LPR engine captures and reads the truck's license plate.

The traffic light switches to red, ensuring the truck remains stationary during the process.

The license plate number is linked in the database with the previously detected container code.

This ensures that both readings are tied to the same truck for tracking and verification.

While PPD engines are still processing as busy, Metrici prevents the barrier from opening for another truck, avoiding overlap in detection.

Once the current truck clears the area and the PPD engines are free, the system allows the next truck to proceed.

The first barrier is lifted, enabling the next truck in line to enter.

Automated detection and recognition of both container codes and license plates.

Traffic light integration to control truck movement during scanning.

Database association ensuring accurate linkage between container and truck.

Barrier control logic preventing multiple trucks from entering simultaneously.

Data for the Durres installation

- 6 CCR detection engines

- 5 LPR detection engines

- 2 Metrici PPD engines

- 1 Metrici Line Counter engine

- 3 Metrici Web Interface- LPR, CCR and PPD

- 1 tailored firmware for Barix Barionet with port acces and traffic logic

- 1 Server

- 14 cameras

Special development and fine software settings and tuning are used in implementing the project as the detection flow may be different in normal traffic vs when traffic jams and queues are formed. For example, a plate number can be read at a certain point, but the container code may become visible after a certain amount of time, or the other way around and all events must be cross-linked- the plate number must be associated with the appropriate container code.

Results and benefits

Streamlined truck entry process.

Reduced human error in container and license plate matching.

Improved traffic safety and flow management.

Enhanced operational efficiency in port logistics.

The authorities as well as the private operator for the terminals wanted to know which truck transported which container and how long it stayed on load or inside the terminal.

This will better improve efficiency in the future.

All events are sent to a centralized operation center and management software. Besides that, the administrator has full access to Metrici Interface and all its statistics, reports and events. Alerts and blacklists can also be created independently in the Interface for alarms when certain License plates or container codes are detected.

Similar installation are used in some other Metrici projects, where also the drivers are guided to truck loading stations using Metrici LED Displays and showing information about which turn to take and where to go.

This could be the case in the future at this installation also.