- home

-

Products

- Products

- Metrici Custom Applications

- Metrici LPR

- Metrici LPR Parking Module

- Metrici LPR Toll Station Module

- Metrici LPR Weighing Module

- Metrici PPD

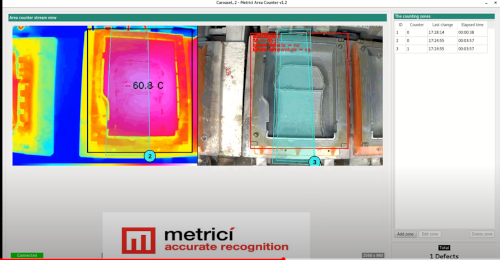

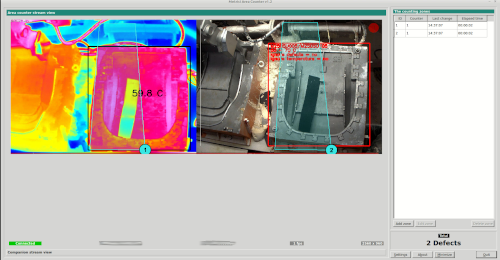

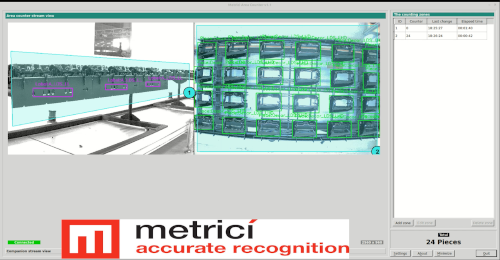

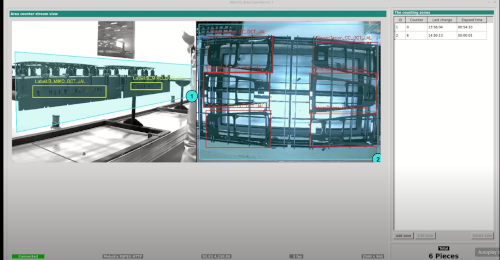

- Metrici Area Counter

- Metrici Line Counter

- Metrici QR Code Reader

- Metrici Container Code Recognition

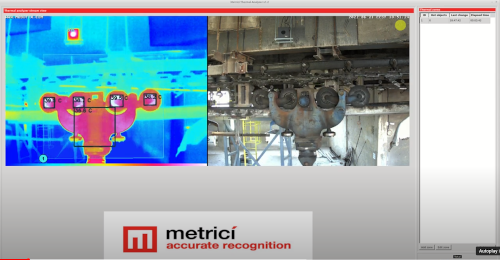

- Metrici Thermal Analyzer

- Metrici Car Kit

- Metrici Server Systems

- Metrici Observer Radar

- Metrici LED Display

- Metrici MultiController

- Metrici LAN Controller

- case studies

- Applications

- Resources

- news

- videos

- Contact

Success Stories

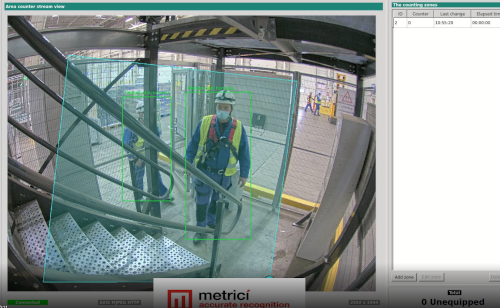

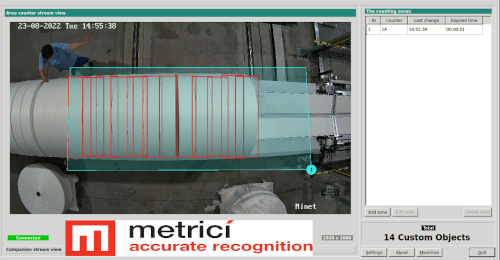

Over the past years, Metrici developed so many custom projects with AI cappabilities. For near each one of them a special training was done for the deep neuronal network to rocgnize different objects or situations, as our client needed. Some of them are adaptation of the standard offer. For example, a human is detected, but afterwards Metrici must identify other elements in the frame to know if certain conditions are met or nor and raise alarms. Get inspired by our work.

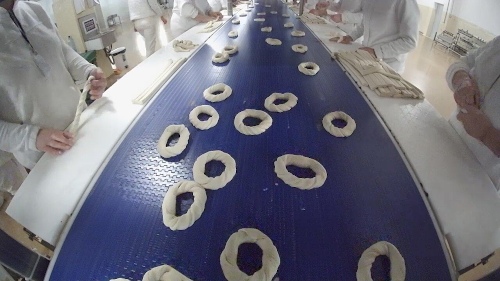

Food industry – bakery

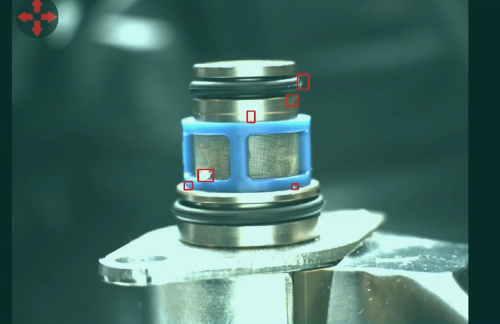

Auto industry production line

Services – waste disposal

Services- safety equipment

Production – textile industry

Production – auto industry

Production – auto industry

Production – chemical industry

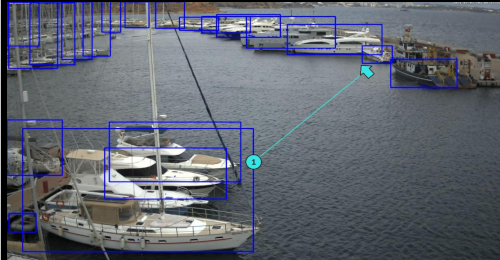

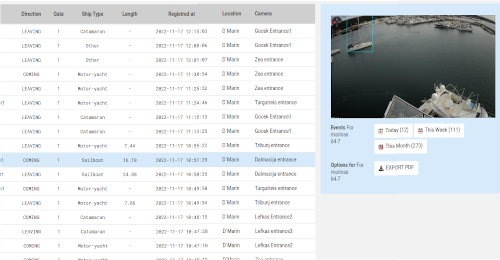

Marina management

Services-Bank Industry

Bottle production and packaging

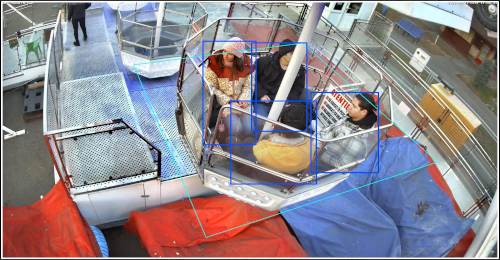

Services- amusement park