- home

-

Products

- Products

- Metrici Custom Applications

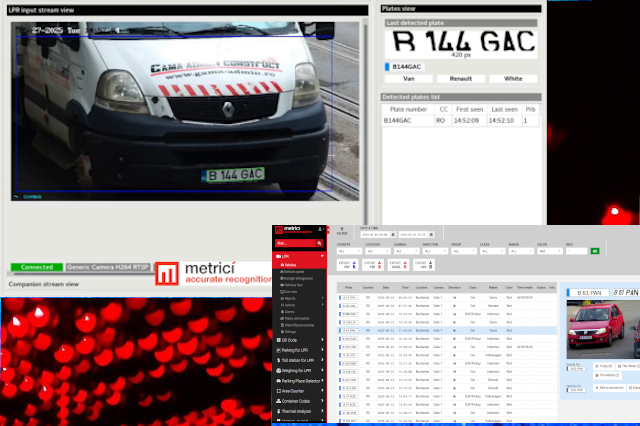

- Metrici LPR

- Metrici LPR Parking Module

- Metrici LPR Toll Station Module

- Metrici LPR Weighing Module

- Metrici PPD

- Metrici Area Counter

- Metrici Line Counter

- Metrici QR Code Reader

- Metrici Container Code Recognition

- Metrici Thermal Analyzer

- Metrici Car Kit

- Metrici Server Systems

- Metrici Observer Radar

- Metrici LED Display

- Metrici MultiController

- Metrici LAN Controller

- case studies

- Applications

- Resources

- news

- videos

- Contact

Valplast chooses Metrici Weighing Station Module

Mission

Valplast Industrie is the biggest name in PVC pipes production and plastic material for sewing, drainage, water wells and protection of electric and communication cables in Romania.

Its activity started in 2001 and the production and distribution extended every year, with warehouses, distribution centers and production units all over Romania.

As a pilot project, the company wanted to monitor one of their many centers and make sure it reduces losses by automating the weighing process. The human factor is often disposed to errors, by mistake or by choice, so the process of car and truck weighing and the recording of the events needed to be automated.

The client wanted to monitor every vehicle entering and exiting the facility and to eliminate losses and thefts from the storage depot. It wanted to implement a fully automated solution for control access and weighing, checking vehicles 24/7, with no restriction.

Solution

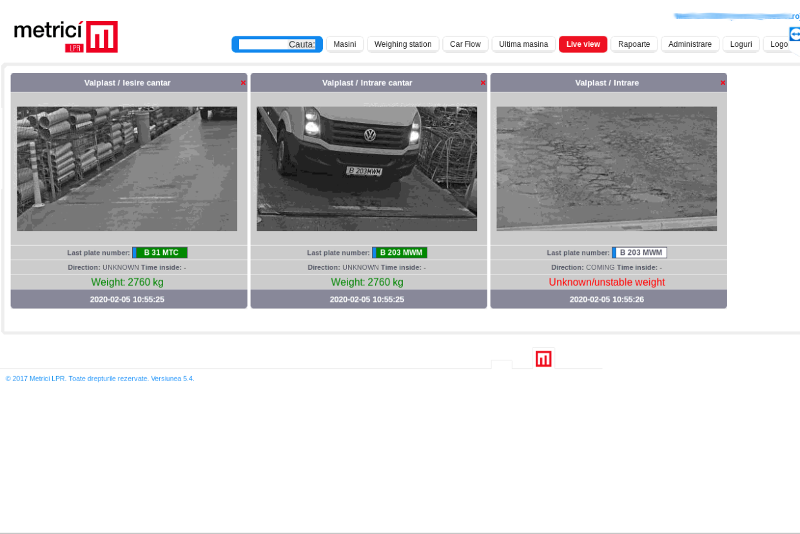

Metrici, along the integrator Tritech proposed the monitoring of the weighing station with three LPR cameras and other hardware devices. The location had two barriers already installed.

In addition to this, the team installed three sensors: two at the ends of the weighing station and one looking in diagonal so that depending on which ones are covered, a trigger is sent to Metrici to start detection for either sides of the station.

Traffic lights at each end of the station indicate the driver that he positioned the vehicle correctly. Also a special and dedicated interface was designed especially for this type of projects.

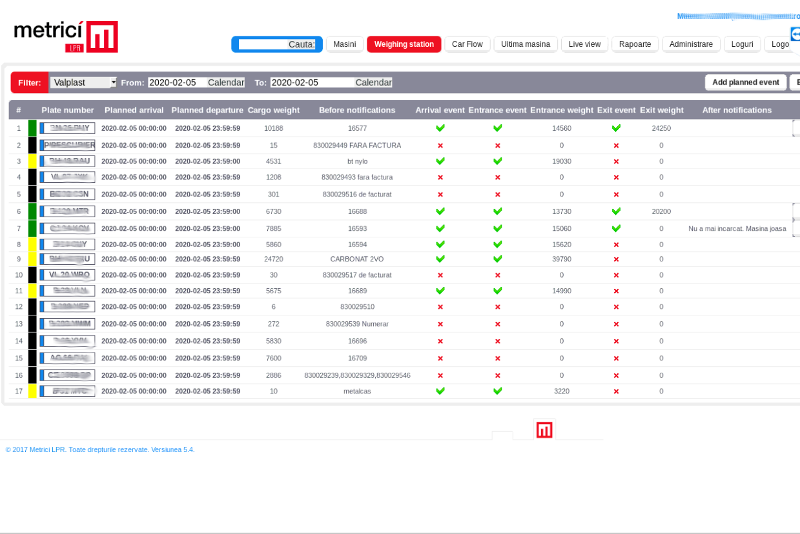

As such, prior to arrival of vehicles, the administrator creates a list of cars that will be weighed in the future.

The rows to be filled by the administrator are: plate number, arrival date and time, planned departure date and time, cargo weight, the other fields will be automatically filled by the Metrici system as the event is developing. The interface is color coded for an easy use. Not all fields are mandatory.

When a vehicle approaches the camera, the license plate is detected and the first barrier opens for the vehicle to come on the weighing station, if that particular license plate was introduced in the action list.

This setting can also be activated for all cars that are approaching the barrier, no matter if they are introduced or not in the special action list. A rule can be set to open the barrier and initiate weighing process for all detected cars. In that case, with the first step, the cars are automatically introduced in the Metrici process list.

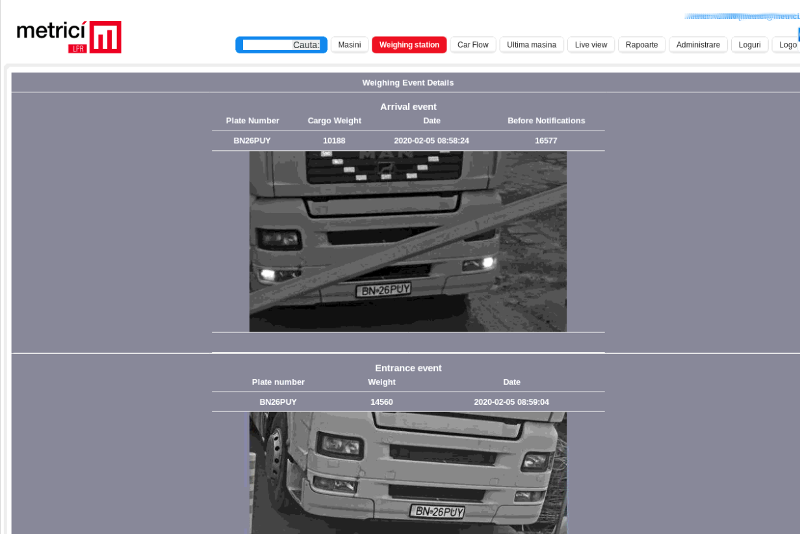

The vehicle positions itself on the station where the sensors are monitoring the scale. When two sensors are obstructed: one that is perpendicular to the scale and one on diagonal, a trigger is sent to Metrici to begin the LPR detection and register the weight.

A green light informs the driver that he positioned the vehicle as it should. A given waiting period is counted down for the weight to be stable, after which Metrici does the LPR detection and records the weight. The event is introduced in database: with a photo, the weight and time stamp. The event is also introduced in the special interface at the “entrance weight” filled.

At the exit, the vehicle is weighed again and Metrici does a calculation, comparing the weight from the arrival with the weight registered at the exit and how much cargo was supposed to be on that vehicle as was filled in by the administrator in the Metrici Interface.

If the deviation is more than x percent (definable in the interface) an alert is issued and the barrier for the exit does not open until further human verification of the vehicle and cargo is completed. A mail alarm is sent to predefined email addresses.

Valplast technical data

- 3 Axis P1425-LE cameras

- 3 laser senzors

- 3 barriers

- 2 traffic lights

- 1 central server

- 3 Metrici licenses

- Dedicated software solution and implementation

- Weighing station integration

- Full automation for access, weighing process and exit

- Dedicated alarms

- Dedicated firmware for Barix Barionet

- integration with external database

Results

After the result at the pilot implementation, Valplast intends to integrate the solution at all of its locations in Romania.

The solution is now available to any user who wants to automate a weighing process and was adopted by many companies.